Tank integrity inspections and testing may apply to any site subject to the Oil Pollution Prevention Regulations, 40 CFR Part 112. The Oil Pollution Prevention Regulations apply to sites engaged in drilling, producing, gathering, storing, processing, refining, transferring, distributing, using, or consuming oil and oil products, which due to location, could reasonably be expected to discharge oil in quantities that may be harmful. A facility that is subject to this regulation, with aggregate aboveground storage capacity greater than 1,320 gallons, is required to have a Spill Prevention, Control, and Countermeasure (SPCC) Plan and possibly a Facility Response Plan (FRP). These plans are to address integrity inspections and testing depending on container capacity and orientation.

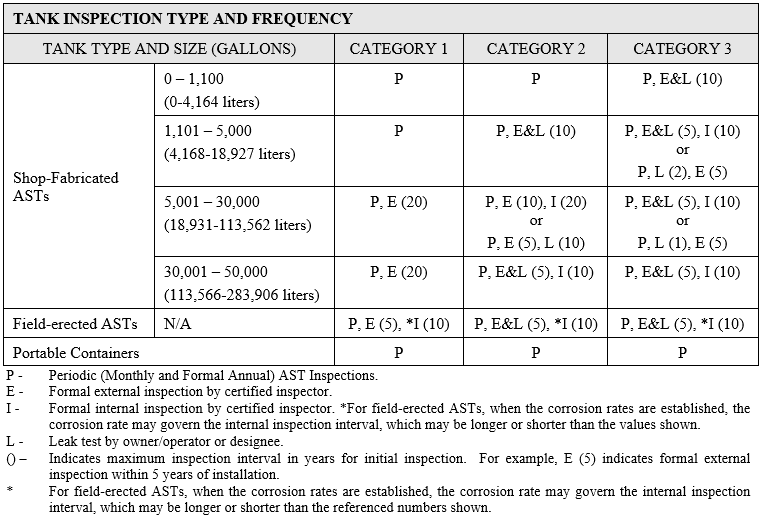

The inspections and testing are typically required to be performed on a regular schedule. Inspections on a ‘regular schedule’ means testing per industry standards or at a frequency sufficient to prevent discharges. Tank integrity inspections and testing for tanks or containers should be conducted by a certified inspector in accordance with the Steel Tank Institute’s (STI) Standard for the Inspection of Aboveground Storage Tanks (SP001) guidelines or other applicable standards and guidelines (e.g., API 653). The STI SP001 inspection type and frequency for various tank sizes and categories are provided below:

Integrity inspections and testing are a necessary component of any good oil discharge prevention plan to determine tank suitability for service and prevent potential discharges. For questions about Tank Integrity Inspection and Testing, SPCC Plan, or FRP requirements, contact Environmental Compliance & Safety, Inc. at:

- Phone: (662) 840 5945

- Website: https://envirocomp.net/contact/